Crane collapses onto apartment block at Wolli Creek; residents unable to return home

Three workers were injured when the crane fell, with the construction union condemning the incident as “not good enough”. Two

Address

2170 Carpenter Street Abbotsford, BC V2T 6B4

Three workers were injured when the crane fell, with the construction union condemning the incident as “not good enough”. Two

Perched high above a Children’s Mercy Hospital construction site, Carl Potter gently moves his left wrist and the 100-plus-foot tower

Larnaca District Court on Thursday acquitted the operator of a 200-tonne tower crane that fell on to Phinikoudes promenade in

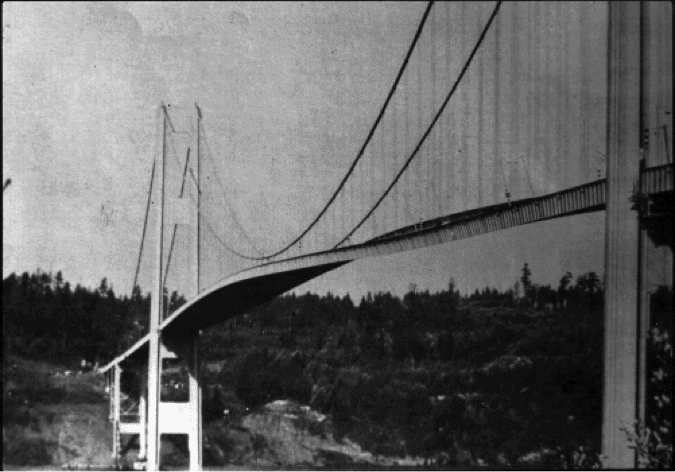

Wind monitoring is key during all life cycle stages of a public bridge, from design and construction to operation and

There is a basic rule that applies for any construction project: preventing accidents is much cheaper than fixing the damage,

Being a construction manager involves taking quick decisions and reacting to unpredictable situations. When determining if weather conditions are suitable

DEALING WITH DOWNTIME DISPUTES IN THE CONSTRUCTION INDUSTRY Anybody working in the construction industry knows that working at height is

SM and the Cloud – Revolutionising the Construction Industry GSM (Global System for Mobile Communications) is the standard developed by